Table Of Contents

- What Is A Small Manufacturing Business?

- Top Small Manufacturing Business Ideas

- Low-Investment & Home-Based Manufacturing

- Traditional & Local Market Manufacturing

- Tech-Driven & Modern Manufacturing

- How To Start A Small Manufacturing Business (Step-By-Step)

- 1. Conduct Market Research & Idea Validation

- 2. Write A Solid Business Plan

- 3. Legal Framework & Registration

- 4. Funding & Capital Planning

- 5. Set up Production & Operations

- 6. Quality Control & SOPs

- 7. Sales & Marketing Strategy

- Cost Breakdown & Profit Estimation

- 1. The Initial "Start-Up" Stack

- 2. Fixed vs. Operating Costs

- · Fixed Costs

- · Operating (Variable) Costs

- 3. Profit Margin Scenarios

- · Hand-Poured Soy Candles

- · Eco-Friendly Tote Bags

- · Small Electronics (e.g., Smart Home Sensors)

- 4. The Break-Even Point

- 5. 2026 Pro Tip: The "Buffer" Fund

- Key Challenges & How To Overcome Them

- Supply Chain Snags

- Fighting The Giants

- Regulatory Red Flags

- Finding Great People

- Expert Tips & Best Practices For Small Manufacturers

- · Master The Lean Lifestyle

- · Always Be Improving

- · Go Green To Get Green

- · Safety Is Your Shield

- Frequently Asked Questions

How To Start And Grow A Profitable Small Manufacturing Business In 2026 (Step-by-Step Guide)

The economic trends of 2026 currently favor small manufacturing businesses, which have begun to establish themselves in the market.

Small manufacturers in the United States operate as flexible organizations with small teams and limited earnings.

And yet, they make up the largest share of the industry while developing new products and meeting rapidly changing customer demands.

Furthermore, industry experts report that small and medium manufacturers comprise almost all manufacturing companies in the United States.

This shows their continuous presence in the market and their ability to endure challenges.

In particular, the rising demand for locally produced, personalized, and ethically sourced products drives this growth.

Consequently, shoppers increasingly select products that offer local options.

This delivers sustainability benefits and distinctive features instead of choosing common imported items.

The manufacturing industry gains new opportunities through this trend. This helps small businesses that specialize in particular markets.

Moreover, commercial research shows multiple ways to operate small manufacturing businesses through artisanal products and technology-based production methods. This helps to meet current market needs.

Ultimately, small manufacturing businesses create essential economic value for their communities through their production activities.

These businesses create employment opportunities by partnering with suppliers and use their profits to invest in their communities.

It helps develop local economic systems. This complete guide will show you all the necessary steps to build and expand your successful small manufacturing enterprise in 2026.

What Is A Small Manufacturing Business?

The small manufacturing business establishes physical production capacity through

- reduced employee count,

- lower financing requirements,

- operational system

This operates between two extreme points of manufacturing capacity. Therefore, small manufacturers use flexible production methods to create specialized products.

They also produce in short production runs and deliver to customers quickly.

For example, some businesses produce finished consumer goods, which include furniture, food products, and personal care items.

Then there are a few that produce industrial components. This includes metal parts and packaging, as well as electronic assemblies.

They create specialty products designed for specific customers. The scope is broad, but the common thread is controlled scale and hands-on operations.

Specifically, most small manufacturers follow one of three models:

- Batch manufacturing (which produces goods in small lots),

- Custom production or made-to-order production

- On-demand manufacturing, which depends on real-time orders.

The inventory collection system for each model protects businesses from inventory losses while enabling them to maintain their pricing and profitability.

The requirements of regulatory systems differ between nations. Small manufacturers must follow

- U.S. federal, state, and local licensing requirements,

- Tax regulations and safety standards.

Similarly, the regulatory environment in India establishes its framework through

- MSME classification,

- Udyam registration, and

- GST compliance requirements.

A basic understanding of these matters will prevent costly compliance problems later.

Top Small Manufacturing Business Ideas

The most effective method for assessing small manufacturing business opportunities is to establish three categories that reflect their investment needs, market demand, and potential for business growth.

In 2026, the most profitable ideas fall into three clear categories.

Low-Investment & Home-Based Manufacturing

These businesses are ideal solutions for entrepreneurs!

These people want to build their own business from the ground up. And along with that, testing market demand and expanding their operations does not stop either!

That too is possible, without needing additional operational facilities. Commonly chosen products include:

- Handmade candles, soaps, and skincare products that exist because customers prefer clean-label products and artisanal brands

- Paper products, which include bags, notebooks, and custom stationery

- Eco-friendly small goods, which include reusable household items

- Custom 3D-printed items, which include prototypes, accessories, and personalized products

The following explanation shows why this system functions effectively:

- The system requires minimal equipment and space to operate

- The system provides simple startup options through eCommerce platforms and online marketplaces

The investment range: $2,000 to $15,000

The Advantages: Reduced risk and quick establishment

The Challenges: High competition and the necessity to build a brand identity for future development

The market demand: It shows strong growth, which will continue to grow in the future.

Traditional & Local Market Manufacturing

Niche U.S. communities and export markets create consistent consumption patterns. This way, it can fulfill cultural demands for these businesses.

Common product categories:

- Incense sticks and textile accessories

- Paper plates and disposable products

- Organic snacks and food processing items

- Toys and craft-based goods

Why this works:

- Repeat purchases and predictable demand

- Retail sales in ethnic markets, plus bulk order sales and export sales, show strong business results

Investment range: $15,000–$50,000

The advantages: The business has stable sales because it sells to bulk buyers

The challenges: The business needs to follow regulations, which results in higher expenses and reduced profits

The Demand: Product demand will remain constant as long as export opportunities exist in the market.

Tech-Driven & Modern Manufacturing

This category shows the future direction of manufacturing. This will use three main elements: automation, customized production, and digital technology integration.

The following markets show potential for strong growth:

- Small electronic components and accessories

- Portable chargers and power solutions

- Eco-friendly and smart packaging

- Customized furniture and décor using CNC or modular systems

The following reasons explain why this approach succeeds:

- Higher margins through customization

- Digital tools provide better inventory management capabilities

Investment range: This project typically falls between between $40,000 and $150,000

The Advantages: The system provides benefits because it can grow and develop for future needs

The challenges: The system requires higher expenses for initial establishment, while demanding specialized knowledge

The demand: The product demand will reach a peak and continue to grow.

How To Start A Small Manufacturing Business (Step-By-Step)

Are you prepared to transform your product concept into a tangible product?

Starting a manufacturing unit in 2026 is easier than ever thanks to smart tech and global demand.

The following guide provides you with the necessary steps to create a brand that will continue executing its mission beyond your lifetime.

1. Conduct Market Research & Idea Validation

Building in the dark is a poor approach to development. Google Trends lets you observe current user search behavior.

Use social media surveys to determine which solution your customers prefer. Analyze your competitors to discover.

These aspects of your product can help you to improve through

- Faster delivery,

- Reduced costs

- Better quality.

You must first validate demand before making any equipment purchase.

2. Write A Solid Business Plan

This document serves as your GPS navigation system. Your Unique Selling Proposition (USP) requires you to identify which elements of your business make you different from competitors.

You need to present your initial business expenses, including:

- Operational costs

- Projected income.

A clear plan isn’t just for you. It’s essential if you want to convince banks or investors to fund your vision.

3. Legal Framework & Registration

You need to select an official business structure, such as an LLC or a Private Limited Company.

Your company must complete the official company registration process through the Ministry of Corporate Affairs (MCA) to receive its Incorporation Certificate.

You can simply MCA v3 login to complete the entire process.

In India, register on the Udyam Portal to avail MSME benefits and obtain your GST number.

The trademark registration process through the IP India portal protects your brand name and logo from unauthorized reproduction.

Also Check: 31 Unique Business Name Ideas For Startups In 2026

4. Funding & Capital Planning

What methods will you utilize to cover your expenses? You have two options: bootstrap with your savings or explore government schemes, including Make in India.

The SIDBI website offers information about small business loan options.

If your product is innovative, try crowdfunding on Kickstarter or pitching to angel investors who love hardware.

5. Set up Production & Operations

The location needs to be determined because it will provide essential advantages for businesses that need to maintain proximity to their suppliers to minimize transportation costs.

Evaluate your budget requirements to determine whether actual new equipment purchases are necessary or if you can use certified refurbished equipment instead.

Apply Lean Manufacturing principles by maintaining an organized layout. This enables efficient operations through waste reduction and fast operational movement.

6. Quality Control & SOPs

Your brand needs to deliver consistent results because this approach creates the most effective marketing strategy for your business.

Document all Standard Operating Procedures (SOPs) to ensure that every product receives identical manufacturing treatment.

Create basic checklists that track the “Incoming Parts” stage, the “In-Progress Assembly” stage, and the “Final Polish” stage.

Shipments will only occur once products achieve complete perfection.

7. Sales & Marketing Strategy

Businesses should not wait for customers to arrive at their establishment. List your products on IndiaMART to generate B2B leads, or start a D2C store on Shopify.

Use SEO to show up when wholesalers search for your product.

Customers encounter your product through its attractive packaging. This establishes their first contact with your brand.

Cost Breakdown & Profit Estimation

Your manufacturing vision for 2026 requires you to master all numerical aspects of your business operations.

Don’t let the math scare you! Your understanding of cash flow determines whether you operate a hobby or run a successful manufacturing business.

1. The Initial “Start-Up” Stack

You must complete all your initial expenses before you can activate your equipment. Your entry pass comes in the form of these expenses.

- Machinery & Tools: This is usually your biggest hit. In 2026, many small US makers are opting for “smart” modular machines or high-end 3D printers that scale with you.

- The Legal Bundle: The budget should include expenses for registering the business through LLC formation and for trademark registration at the USPTO.

The typical price range for this service is $500 to $2,500, depending on your state and the number of product categories you wish to safeguard.

- Initial Inventory: You will require your initial stock of unprocessed materials to produce your first set of prototypes and market-ready products.

2. Fixed vs. Operating Costs

You need to track your monthly expenses because your sales volume can range from 1 product to 1,000. Your expenses remain constant regardless of your production level

· Fixed Costs

These stay the same. Studio space rental, general liability insurance, and accounting software subscriptions are all fixed costs that will remain constant.

· Operating (Variable) Costs

These costs vary with the quantity of products you manufacture. The company requires additional materials and sustainable packaging, and shipping costs increase as order volume rises.

In 2026, business owners use cloud-based inventory systems to operate their businesses with continuous inventory visibility.

3. Profit Margin Scenarios

How much will you actually pocket? Let’s look at three popular 2026 niches:

· Hand-Poured Soy Candles

These high-margin products demonstrate their economic value. A candle costing $5 to make (wax, wick, jar, scent) often sells for $25+.

That results in a higher gross margin for the business.

· Eco-Friendly Tote Bags

These products generate revenue through their high production volumes. The product costs $4 to create from recycled materials.

This allows you to sell it in bulk at $8 or through retail at $15. Also, the products have lower profit margins, yet you will likely sell multiple items to nearby stores.

· Small Electronics (e.g., Smart Home Sensors)

The product requires expensive components. The retail price for a gadget that costs $15 to build will be $45. On top of that, your margin needs to cover high R&D and potential tech support costs.

4. The Break-Even Point

This number represents the units you need to sell to recover all your expenses. To find it, divide your Total Fixed Costs by your Profit per Unit.

Example: If your rent and software are $2,000/month and you make $20 profit per candle, you need to sell 100 candles just to hit zero.

The first 100 candles you sell will only help you reach break even point, while all subsequent sales will bring you total profit.

5. 2026 Pro Tip: The “Buffer” Fund

Your business needs a fund that will cover unexpected expenses at a 15% rate. Your production process maintains continuous operation.

Reason? Well, it is because you have a financial reserve that protects against unexpected shipping cost increases and equipment breakdowns.

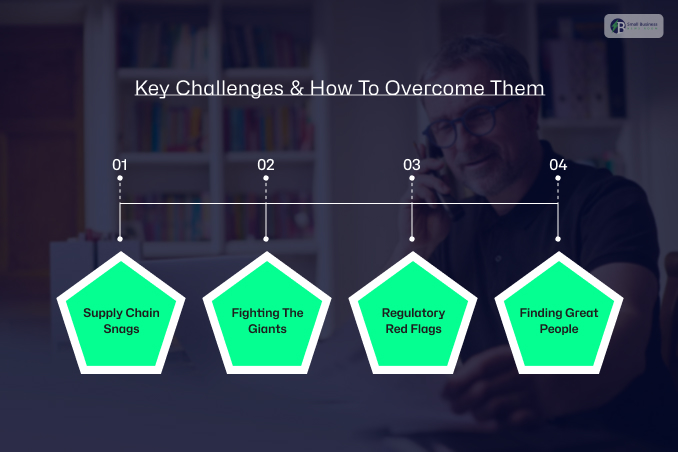

Key Challenges & How To Overcome Them

The business world will experience exciting changes as entrepreneurs launch new ventures in 2026, despite various challenges.

The following guide will teach you how to manage these situations like an experienced professional.

Supply Chain Snags

Shipping delays are real. Businesses should avoid depending on a single supplier. Create a secondary vendor list that includes nearby US suppliers.

Moreover, the more expensive options will protect you during periods when global shipping operations are disrupted.

Fighting The Giants

Your company needs to demonstrate its unique story because you cannot match the lower prices of bigger companies.

Use your “Small Business” status as a badge of honor. Customers in 2026 love buying products with a face and a mission behind them.

Regulatory Red Flags

The costs of mistakes in this area can be high. The “I will complete it later” tendency should be avoided while dealing with safety requirements.

You need to verify your workspace’s compliance with OSHA rules before the trademark registration deadline. On top of that, legal compliance costs less than paying penalties for violations.

Finding Great People

The process of finding skilled workers remains challenging. The search for ideal specialists should begin with people who demonstrate strong positive qualities.

Automated training tools should be included in your budget because they provide basic instruction on the necessary skills.

Expert Tips & Best Practices For Small Manufacturers

Do you want to transform your small store into an efficient operational system? The following professional practices distinguish expert performers from beginner workers in 2026.

· Master The Lean Lifestyle

The 5S method (Sort, Set in order, Shine, Standardize, Sustain) provides a framework for maintaining organized workspace areas.

When you have not used a tool for thirty days, turn it to another location. A clean floor offers more than visual appeal. It reduces accidents and enhances operational efficiency.

· Always Be Improving

The organization should implement a policy requiring employees to improve their work performance by 1% each day.

The assembly process requires me to dedicate ten minutes every Friday to finding one improvement opportunity.

The process of continuous improvement enables your organization to reduce expenses while maintaining exceptional product quality throughout its growth phase.

· Go Green To Get Green

US consumers consider sustainability to be one of their most important buying factors in 2026.

The business should implement plastic-free packaging and use recycled materials as its primary resource.

The company should promote its sustainable practices through its marketing efforts.

Eco-friendly practices benefit the environment while creating strong customer loyalty towards your business.

· Safety Is Your Shield

Your company can experience a total operational shutdown after a single workplace incident.

The organization should conduct monthly safety inspections to exceed OSHA mandatory standards.

Your organization needs to ensure that equipment receives proper upkeep while team members undergo necessary training.

Frequently Asked Questions

You can establish your company through manufacturing processes that create low-footprint items.

Additionally, this collection includes 3D-printed products, clothing, and artisanal food items! As long as you comply with the zoning regulations and safety standards of your local area.

The most suitable options include

• Sustainable packaging solutions

• Customized 3D-printed medical products

• Intelligent residential monitoring devices

• Products made from recycled textiles.

The current market demands environmentally friendly products that integrate technology, according to socially responsible consumers.

The Udyam Portal provides registration options for businesses seeking MSME status. The company needs to complete its registration process on the MCA website to obtain a GST number and request a PAN/TAN.

In the US, you generally need

• A general business license,

• A sales tax permit, and

• Specific industry permits (like FDA for food or EPA for chemicals) to stay compliant.

Your Unique Selling Proposition (USP) needs to be your main focus, along with production expenses and your complete sales strategy.

Your break-even analysis must show the exact moment your business starts generating profits.