Table Of Contents

Metal Workshop 101: The Difference Between Cnc Cutting & Laser Cutting

Last Updated on: September 11th, 2025

Whether you’re a hobbyist, an expert, or making a job off of it, metal cutting is a skill that can be used for many applications. From simple tasks like cutting metal tubing or bending aluminum sheets to more complicated projects like building vehicles and furniture, metalwork is one of the best ways to express yourself through your craftsmanship.

While some people prefer using traditional tools like shears or hammers when working with metal, there are also many other options available for completing your project. In this article, we’ll discuss two types of cutters—laser cutters and CNC cutters—and how they differ from each other based on their intended uses as well as their pricing models.

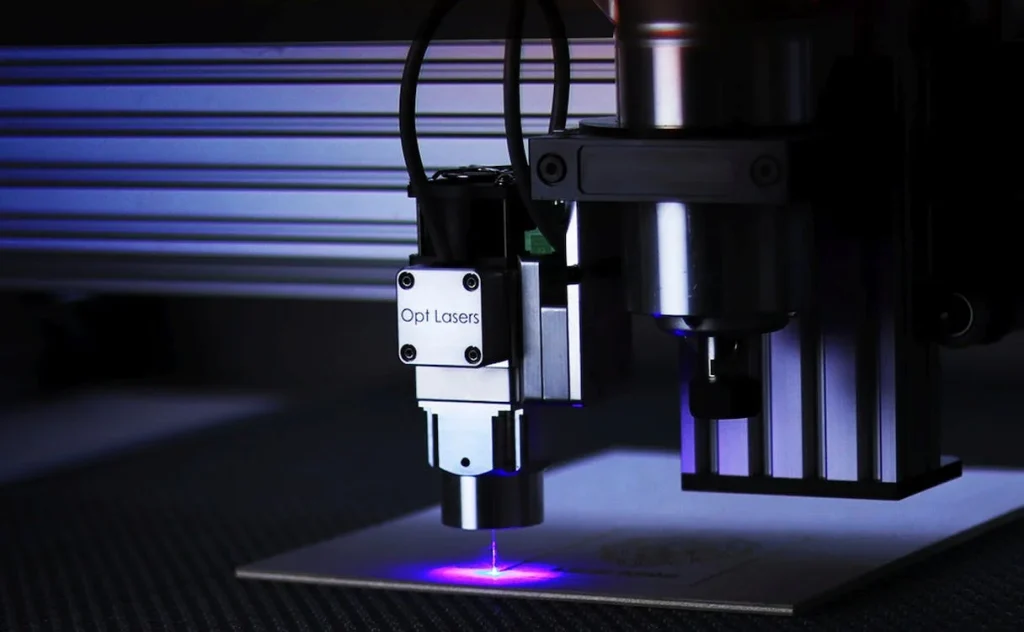

Laser Cutting

Laser cutting is a process that uses a laser beam to cut materials. The laser beam travels through the material and melts the material at the point of contact. Laser cutting is often used to cut certain types of metal, such as stainless steel, carbon steel, and aluminum. Mastercut Technologies are the experts in laser cutting technology, using a new Fibre Laser to make bespoke designs customized for your business.

The speed at which these machines can operate depends on how much power their motors have. Some machines can be operated at up to 40 feet per second (12 meters per second), while others are slower but still fast enough for most cutting jobs.

CNC Cutting

CNC stands for Computer Numerical Control. This means that a computer controls the motion of the machine, which cuts or shapes your material by cutting into it and removing tiny amounts of material at a time. CNC machines are used to cut or shape metal, wood, and plastic.

Many different types of CNC routers in Sydney can be used in a variety of ways depending on what you want to do with them. Some examples include:

- Milling Machines: These machines use spinning tools to remove large amounts of material from objects quickly and efficiently

- Turning Lathes: Turning lathes are similar to milling machines in that they use tools (chisels) to remove large amounts of material from an object but they turn instead of spin as milling machines do

CNC machines can cut complex designs because they use computer software (cad files) that tells the machine exactly where to move its various components to create your desired shape.

Read Also: How To Choose The Right CRM Software For Your Company

Metal Workshop 101: The Difference Between CNC Cutting & Laser Cutting

CNC and laser cutting are both common tools used in metal workshop buildings. CNC stands for computer numerical control, while the laser is an acronym meaning light amplification by stimulated emission of radiation. Despite their names, these two processes are very different. CNC is a method of machining that uses a computerized cutter to carve away material; the more precise a machine is, the better it can produce smooth surfaces without leaving behind jagged edges or other imperfections. Laser cutting involves focused beams of light that cut through materials using heat energy. Depending on the material being cut and its thickness, lasers can create shapes with clean edges or leave them jagged (depending on how powerful your laser is).

Laser and CNC machines aren’t mutually exclusive—in fact, you can use them together! If you want to cut something out with both methods at once using one machine instead of two separate ones then consider investing in a hybrid system like AXIS2 from Concept Laser (which combines both technologies into one package).

Read Also: 3 Simple Ways Your Business Can Use Cloud Services Today!

Which Type Of Cutter Should You Choose For Your Project?

If you want to cut through a lot of material quickly and don’t need a lot of precision, go with the CNC. If you need to cut in detail, like cutting out small shapes or intricate laser-cut designs, then laser cutting would be your best bet.

Conclusion

We hope we’ve helped you understand the basics of both laser cutting and CNC cutting. If you want to learn more about these processes, check out our other articles on the subject. We also have a full library of information about what kind of equipment and tools are available for your metalworking needs, so check it out!

Read Also: